To provide you with the best possible user experience, we use cookies and similar technologies. These include cookies for the operation and optimization of the website and for advertising tailored to your online usage behavior.

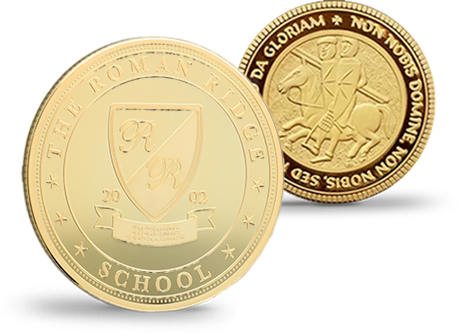

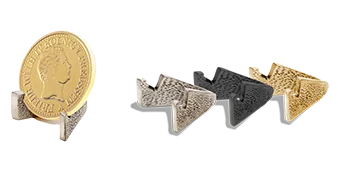

Need a small batch of custom coins? Look no further! Our in=house production facility and diverse manufacturing methods allow us to create coins starting from just one piece. Quick and cost-effective, our engraving or photo printing techniques can deliver a stunning commemorative coin within 5-8 days. For those seeking a premium gift, we also offer high-end embossing using a 300-ton press for pure 24k gold or 999 silver coins of the utmost quality.

Are you looking to get a Custom Coin?

Single minted coins in the highest quality

- Coin production in highest perfection

- Bullion coin quality

- Individual mold carving and production

- Any size, finish and material available

- Choose 24k Gold, 999 Silver or bronze coins with silver and gold plating

- Any size available: 5mm to 160mm

- Production time: 4 – 6 weeks

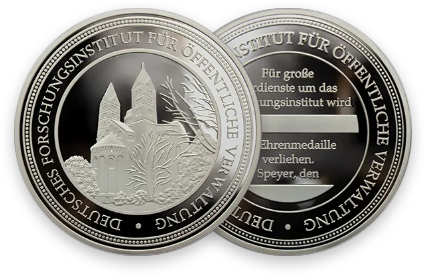

Custom made coins with engraving technique

- You can choose different base coins

- High quality coins made from 999 silver

- You can also choose a silver coin with 24k gold plating

- High-end Bullion coin finish / collector`s coin finish

- We offer different coin sizes: 28mm and 36mm

- Your design is engraved with a diamond to the coin

- Production time: 1-2 weeks

Photo printed colourful custom coins

- We use high quality coins made from pure brass

- You can choose polished gold or silver plated finish

- You can also choose a bronze antique version

- We offer two sizes: 40mm and 80mm

- Your design is printed to the coin and covered with acrylic lacquer for a perfect finish

- Production time: 1-2 weeks

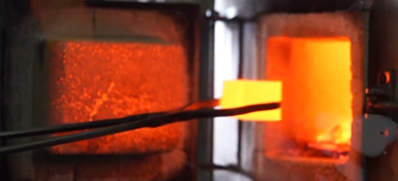

Watch our Video

how a 24k Gold coin

is minted in our

Own production facility

Steps To Produce Custom Coins

Using your unique custom design, our coin designers will transform your concept into a digital graphic. After your approval, this is transferred into a digital 3D model which, in turn, is used to produce the coin minting die. This is done with precision to ensure that every fine detail, lettering, lines or illustration can be actualised with the utmost accuracy on your finished product. Our cutter tools are able to reduce dies down to a tenth of a millimeter.

Since dies only withstand the heavy production processes for a limited time, several of these are made to guarantee that all coins meet our rigorous quality standards.

If a design, logo or theme is available, our coin designer creates a corresponding draft digitally on the screen. After the graphics have been approved, they are transferred into a digital 3D model, which is then used to produce the minting die. When machining the mould, precision is essential so that the very fine lettering, lines or graphics can later be transferred to the coin as accurately as possible. Cutter tools process the dies down to the tenth of a millimetre. Since they wear out relatively soon, several of them are made at the same time so that the coin production can go through in high quality.

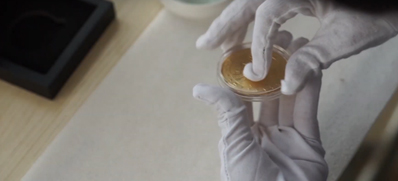

For both cases, the single sided and double sided coin, a die for top and bottom is needed. Accuracy has priority over speed in this processing step. Therefore, the blanks are added to the minting machine by hand and checked individually. Precious metal blanks that do not meet the high standards are sorted out and melted down again. With a pressure of about 100 tons, the motifs are mechanically embossed to the gold and silver rounds. Each minted coin is then carefully checked to ensure that only flawless products are sent to customers. In addition, dies might have to be replaced at regular intervals in order to achieve a consistently high quality.

The finished minted coins can then be further processed. For example, the edge can remain smooth, be hallmarked or have a vertical or angled edge. The edges are also made by hand or by machine. In addition, special laser engravings are also added during the finishing process, such as consecutive serial numbers, through which the coins can be further individualised. After the entire minting process has been completed, the finished precious metal coins are packaged. To protect the surface, gold and silver coins are always packed in high-quality coin capsules. In addition, these can still be placed in elegant cases or floating frames in which the individual coin is decoratively displayed.

Online coin configurator

Upload your existing designs to our Coin Configurator or let our tool provide you with some inspiration.

DESIGN OF YOUR COIN?

We create your coin graphic for free.

Just send us your ideas and images/coats of arms/logos.